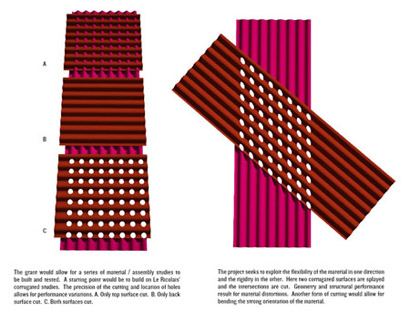

It was Robert Le Ricolais, early pioneer of surface and space frame structures, that said "the art of structure is where to put the holes". His eloquent statement is even more relevant today given the ability to link the precision of the computer with the precision of computer controlled cutting equipment. While his statement was in reference to building-scaled openings, it is true of smaller scale cuts, perforations and slices and his statement highlights the potential of a detail to inform a process.

Digital Fabrication is most often celebrated for the construction of exuberant form achieved through extreme material usage. In this equation computer driven tools process neutral materials, resulting in bins full of saw dust or foam dust. This process perpetuates the idea that form comes first and construction is the act of replicating the form in the most exploitable material.

The Research-Through-Making Grant offers a chance to give material and process an upper-hand where forms might emerges directly through experimentation. This proposal takes a defiant stance against form over material. Two-dimensional cutting of sheet metal offers many opportunities because of the abundance of local shops equipped with cutting technologies and an array of readily available building materials.

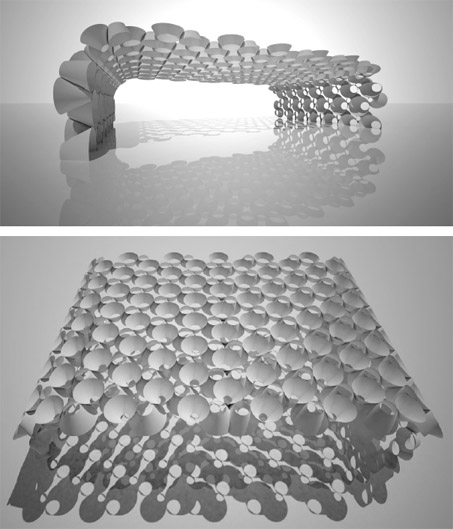

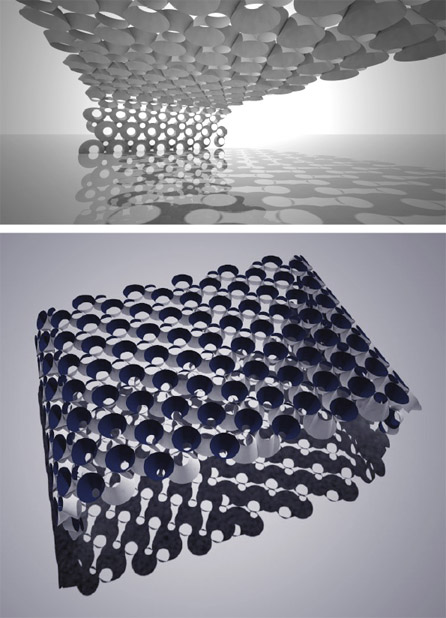

It is in these routinely used tools and materials that a designer can make the most significant impact, altering the landscape of production. 2D cutting is a subtractive process creating a strong conceptual and structural link where the removal of material both reduces weight and potential strength. The use of sheet metal allows for the creation of lattice or surface structures dependant on material properties and material organization. The assembly of the cut sheet metal extends the structural logic through the location of holes or tabs for potentially complex assembly by unskilled labor. This project will be used to build a structure capable of spanning at least 25’ which will require multiple assembled parts to achieve the required length and depth. Beyond the dimensional constraints of most materials available under 25’, the project aims to span beyond the scale of most lost-cost conventional framing systems (standard wood framing) while offering increased material and spatial affects.

The images included in the proposal are to help explain the general themes of the research more than to show that this is what will be built with the funding. The corrugated studies and conical studies are more of a starting point to initiate the research. As feedback is gained from initial material studies, the project and the form may move in different trajectories to fully investigate material outcomes or assembly techniques.

No comments:

Post a Comment